Digital Extruder

Connect the dots of product development from formulation through production for healthier, tastier food products

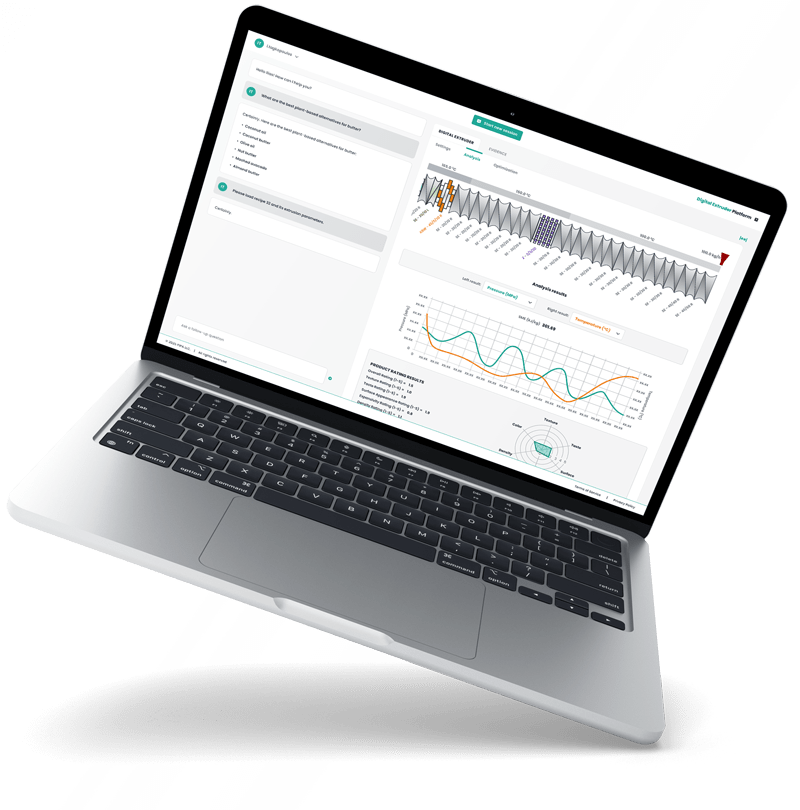

Test unlimited formulations virtually and know exactly how they'll perform in production

Food development traditionally requires extensive resources, time, and capital, with high risks of market failure even after significant investment.

Digital Extruder transforms this process by connecting all critical elements – from formulation through manufacturing processing, and sensory and nutritional outcomes – into one integrated platform.

- Develop nutrient-dense, low-carb foods without compromising taste and texture

- Get products >4x faster to market

- Achieve 600% ROI based on speed-to-market and reductions in energy & material costs

Unlock faster innovation

Address common product development challenges around cost, nutritional value, supply chain and sustainability with the Digital Extrusion platform, a state-of-the-art digital twin SaaS. Digital Extruder uses AI, food science, and computational fluid dynamics (CFD) to simulate a formulation's behavior during food processing. This allows the prediction of optimal extrusion parameters and the resulting sensory characteristics before any bench and lab experiments happen.

PRODUCT RENOVATION

Fine-tune existing recipes or develop new formulations based on your operational and commercial targets.

EXTRUSION PROCESS

Get optimal extrusion settings and material properties recommendations in a matter of seconds.

SENSORY PROFILE

Optimize the sensory signature based on the recipe & extrusion process to improve targets such as flavor or texture.

Applications

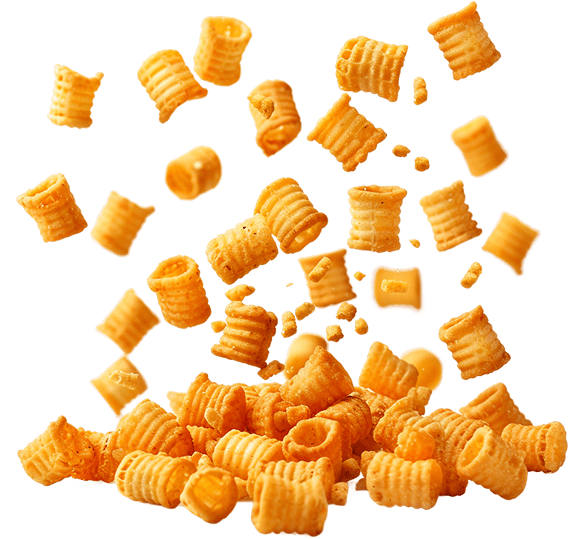

Breakfast Cereal & Snacks

Pasta

& Noodles

& Noodles

Pet

Food

Food

Meat Alternatives

Specialty Products

Industrial Ingredients

CASE STUDY

Rivalz develops nutritious and tasty snack by testing thousands of formulations virtually

Snack company, Rivalz, launched 3 new products to market in just 6 months, a feat that typically takes ~24 months.

Watch the Bloomberg feature on how, Rivalz uses AI to transform product development end-to-end.

Watch the Bloomberg feature on how, Rivalz uses AI to transform product development end-to-end.

Request the brochure

Fill out the form below